Our workshop gantry crane is designed for flexible and efficient indoor lifting. This gantry lifting system handles heavy loads across wide workshop areas without relying on roof structures, making installation straightforward and cost-effective. With customizable spans, lifting heights, and load capacities, it can be tailored to your workshop’s specific needs while minimizing installation and maintenance costs.

Discover Workshop Gantry Crane Types: On-Rail & Mobile

When selecting a gantry crane for workshop, understanding the types available is essential to match your specific material handling needs. Generally, our workshop gantry crane for sale comes in two main configurations – on rails and rubber-tired mobile types, each designed to suit different operational needs and workspace layouts.

Workshop Gantry Cranes on Rails

The gantry workshop cranes on rails are permanently installed and travel along steel rails embedded in the workshop floor. They are ideal for facilities where loads are frequently moved along fixed paths, such as production lines, assembly bays, or maintenance zones.

Single Girder

Feature one main girder, our workshop single girder gantry crane on tracks offers a simpler structure and cost-effective solution for lighter loads. It is perfect for workshops handling moderate-weight materials like steel plates, small machinery components, or precast concrete slabs.

- Load Capacity: 5-20 tons (Customizable)

- Span: 8-35m (Customizable)

- Lifting Height: 6-12m (Customizable)

Double Girder

Equipped with two main girders, double girder gantry crane in workshop provides higher load capacity and increased lifting height. It is suitable for heavy-duty operations where large or bulky items need precise handling.

- Load Capacity: 10-500 tons (Customizable)

- Span: 18-35m (Customizable)

- Lifting Height: 6-18m (Customizable)

Semi-Gantry

One side of the workshop semi gantry crane rides on elevated rails while the other side uses a support leg, allowing installation along open sides or near walls. It is ideal for workshops where space is limited on one side or where full-span cranes are not practical.

- Load Capacity: 5-32 tons (Customizable)

- Span: 12-30m (Customizable)

- Lifting Height: 6-12m (Customizable)

Rubber Tyred Mobile Workshop Gantry Cranes

Rubber tyred mobile workshop gantry cranes move on wheels instead of rails, giving them the flexibility to operate across different locations within a workshop. They are perfect for workshops with variable workflows or where installation of rails is not feasible.

Single Beam

The single beam rubber tyred gantry crane in workshop is designed for moderate loads, easy to maneuver, and cost-effective. It can cover multiple workstations in the same workshop, increasing operational flexibility.

- Load Capacity: 10-150 tons (Customizable)

- Span: 5-20m (Customizable)

- Lifting Height: 6-12m (Customizable)

Double Beam

Our double beam rubber tyred gantry crane for workshop offers higher lifting capacity and greater stability for heavier loads. It is ideal for workshops handling large machinery, heavy steel structures, or multiple tons of precast concrete components.

- Load Capacity: 20-500 tons (Customizable)

- Span: 5-30m (Customizable)

- Lifting Height: 6-30m (Customizable)

Each design serves a distinct purpose, and the right choice depends on your workspace, load requirements, and frequency of operation. Whether you need the precision and stability of a crane on rails or the mobility of a rubber-tired model, Aicrane offers tailor-made solutions to match your workshop’s lifting challenges.

To illustrate this, let’s look at a few real workshop gantry crane projects, where tailored designs have helped our customers achieve safer, more efficient, and cost-effective lifting performance.

Workshop Gantry Crane Projects: Custom Lifting Solutions in Action

Every workshop faces different lifting challenges – from limited roof load capacity to changing layouts. The following real projects show how different types of workshop gantry cranes were selected to perfectly match each customer’s conditions, providing safe, efficient, and cost-effective lifting performance.

120 Ton Workshop Gantry Crane for Machinery Manufacturing in Russia

Working Condition:

- Heavy machinery components up to 120 tons

- Existing building structure unable to support the required lifting loads

Solution:

- 120/32-ton double girder workshop gantry on rails, 18-meter span, dual trolleys for synchronized lifting

Why This Type:

- Stronger ground-based support – avoided costly structure reinforcement

- Stable and precise lifting of large, unbalanced parts

- More economical and safer than an overhead crane for this load range

10 Ton Workshop Gantry Crane for Precast Concrete Handling in Indonesia

Working Condition:

- Lifting concrete beams and slabs between production zones

- Light workshop structure not suitable for overhead runways

Solution:

- 10-ton single girder gantry crane in workshop, 14-meter span, 8-meter lifting height

Why This Type:

- No need for structural reinforcement or building support

- Quick installation on workshop floor

- Low-cost, efficient, and easy maintenance in a dusty concrete environment

Mobile Workshop Gantry for Automotive Injection Mold Handling in the USA

Working Condition:

- Heavy automotive injection molds moved between multiple stations

- Customer wanted to avoid floor excavation and protect existing facilities

Solution:

- 32/20-ton rubber-tired mobile gantry crane for workshop, 11.7m span, 7.7m lifting height, 9.5m total height

Why This Type:

- No fixed rails required – full flexibility for layout changes

- Preserves floor and building integrity

- Precise steering and wireless control for safe indoor maneuvering

Workshop Semi Gantry Cranes for Plastic Injection Mold Handling in Uzbekistan

Working Condition:

- Large-span workshop with no suitable roof structure to support a wide-span overhead crane

Solution:

- Two 20+10 ton semi gantry cranes in workshop, 34m span, 8.72m lifting height, A5 work duty

Why This Type:

- Used existing building columns on one side, rail support on the other

- Saved space and reduced cost compared with a full gantry or overhead crane

These workshop gantry crane projects show that we are committed to designing the right crane type for each customer’s unique workshop conditions, taking into account specific workflows, space constraints, and operational requirements.

Looking to tailor a gantry crane for your own workshop? Next, let’s explore our customization options and see how we can design a gantry crane built specifically for your space, workflow, and operational goals.

Build Your Ideal Workshop Gantry Crane: Custom Design for Your Facility

Every workshop is different – low ceilings, narrow aisles, uneven floors, changing workflows, heavy or oversized loads – all of these create unique lifting challenges. At Aicrane, we start by understanding your workshop and the obstacles you face. Then, we design each gantry crane to address those challenges, ensuring it fits your space, workflow, and operational needs.

Tailored to Your Space: Span and Lifting Height

Workshops often have limited height or floor space, and every inch counts. We measure your facility and design an indoor gantry crane with:

- Optimized span to reach all necessary areas without wasting floor space.

- Lifting height perfectly matched to your workflow, allowing safe handling of materials without obstruction.

Designed for Your Loads: Capacity and Lifting Mechanism

No two workshops handle the same materials. We customize:

- Load capacity for your heaviest items, from light components to machinery.

- Lifting mechanisms and attachments – including hoists, trolleys, hooks, grabbers, or dual-lifting systems – designed to handle oversized, asymmetrical, or delicate loads safely and efficiently.

Optimized Movement: Layout and Travel Paths

Workshops are dynamic spaces with machines, storage, and workers. We design the crane movement to fit your workflow, not disrupt it:

- Strategic placement so the crane serves all key areas efficiently.

- Flexible mobility to adapt to multiple workstations or temporary layouts.

- Collision prevention and safety through carefully planned travel paths.

Easy and Efficient Operation: Control Features

Lifting is only effective if it’s controlled safely and smoothly. We provide:

- Ground or remote control modes tailored to your operator preferences.

- Advanced options like anti-sway systems, sensors, and automation for precise handling.

Built for Your Workshop Environment

Dust, heat, corrosive materials, and continuous operation can challenge standard cranes. We customize:

- Materials and surface treatments to withstand your environment.

- Safety systems such as overload protection, limit switches, and emergency stops specific to your workshop’s workflow.

Our service doesn’t stop at customization. For many customers, the crane is just one part of a much larger picture – the entire workshop structure. That’s why we go beyond manufacturing to offer integrated EPC solutions, covering everything from steel structure workshop design and construction to gantry crane system integration and installation guidance.

Want to build a fully equipped, efficient workshop from the ground up? Next, discover how our EPC one-stop service turns that vision into reality.

One-Stop EPC Solution: From Workshop Design to Gantry Crane Integration

Building a high-performance workshop involves more than just installing a crane – it requires seamless coordination between the building structure, crane system, and operational workflow. That’s why we provide an EPC (Engineering, Procurement, and Construction) solution that brings everything together under one roof.

Integrated Workshop and Gantry Crane Planning

Our engineering team begins by understanding your production layout, material flow, and load handling requirements. Based on this, we design both the steel structure workshop and gantry crane system in perfect harmony. The gantry crane’s span, rail alignment, and operating area are carefully planned according to the workshop layout – including equipment placement, material flow, and floor load conditions – ensuring smooth integration with the production process and avoiding costly adjustments later.

Engineering and Fabrication Excellence

From structural steel fabrication to crane manufacturing, every component is engineered in-house under strict quality control. This ensures precision alignment, structural stability, and consistent performance across the entire facility. Whether your project involves a large-scale heavy machinery plant or a compact production workshop, our EPC approach guarantees that the design and lifting equipment work as one cohesive unit.

Seamless Procurement and Installation

We manage the entire procurement and assembly process – from sourcing high-quality materials to delivering and installing both the workshop steel structure and gantry crane on site. Our installation teams and engineers collaborate closely to align rail systems, test lifting functions, and commission the entire facility efficiently and safely.

Turnkey Delivery and Ongoing Support

Once construction and crane commissioning are complete, you receive a fully operational workshop, ready to handle your lifting tasks from day one. And our commitment doesn’t end there – we continue providing technical guidance, maintenance services, and spare parts support to keep your workshop operating smoothly for years to come.

By integrating steel structure workshop construction and gantry crane systems into a single EPC framework, we help customers save time, reduce coordination costs, and achieve maximum efficiency in their projects. If you’re planning a new workshop or factory, let’s design and build it together – from the ground up, with a gantry crane system that fits your goals perfectly.

In addition, our EPC services extend beyond the workshop and crane system, covering supporting infrastructure such as access roads, drainage and plumbing systems, office buildings, dormitories, and other industrial park facilities. This ensures that your entire project is delivered as a fully coordinated, turnkey solution.

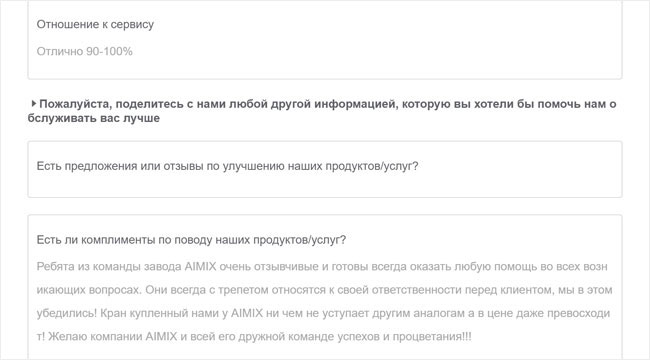

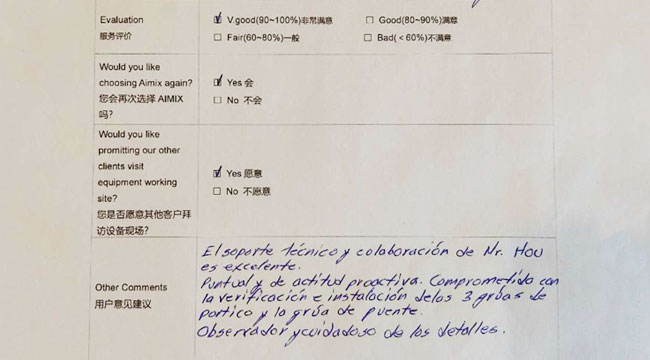

Customer Testimonials: Real Experiences from Workshop Gantry Crane Projects

After designing and delivering customized gantry crane solutions for workshops around the world, we’ve seen firsthand how the right crane can transform workflow, improve safety, and enhance efficiency. Here’s what some of our customers have to say about their experience working with us and the impact our cranes have had on their operations.

– Manufacturing Plant Manager, Kazakhstan

– Workshop Supervisor, Mexico

– Operations Manager, Qatar

We truly value our customers’ feedback and suggestions, as they help us continuously optimize our products and services. We look forward to collaborating with more clients, designing the most efficient, safe, and tailored workshop gantry crane solutions for every facility.

Ready to experience the same level of performance and support in your workshop? Contact us today and let’s discuss how we can create a gantry crane system perfectly suited to your workshop.