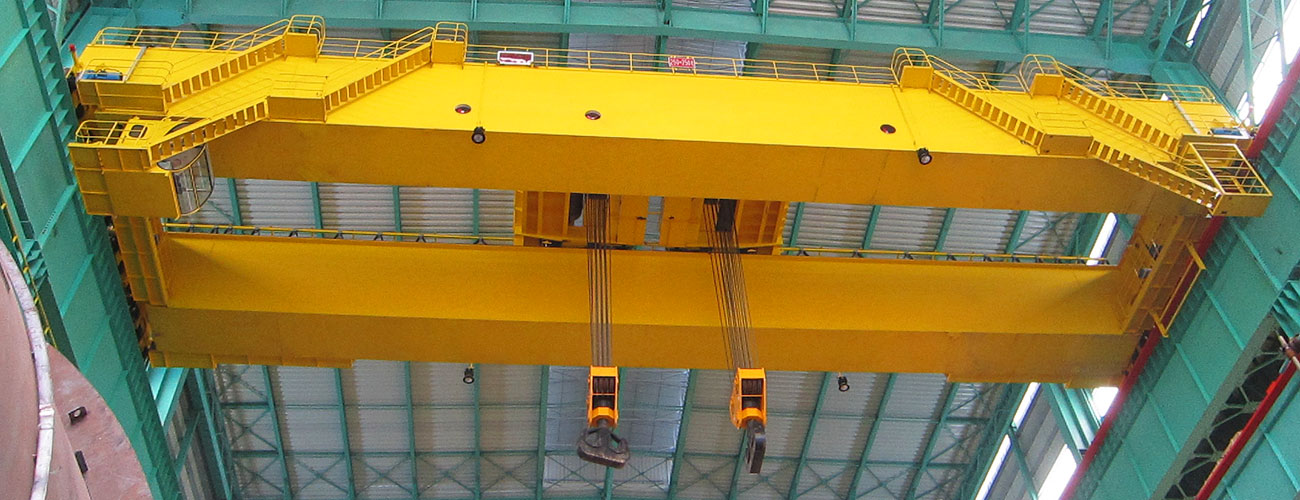

A charging crane is an essential part of modern steelmaking, ensuring efficient and safe feeding of scrap or hot metal into the furnace. Built for extreme heat and heavy loads, Aicrane charging cranes deliver precise, reliable, and continuous performance in demanding steel plant environments.

Charging Crane Technical Specifications – Key Parameters at a Glance

When selecting a charging overhead crane for your steel plant, understanding the technical specifications is crucial for efficient operations and optimal investment. Our charging crane for sale is engineered to handle the demanding conditions of furnace charging while maintaining precision and safety. Key specifications include:

- Lifting Capacity: 20-320 tons, suitable for a range of furnace types

- Span: 10.5-31.5 meters, adaptable to different steel plant layouts

- Lifting Height: 6-24 meters, accommodating furnace and storage heights

- Duty Class: A6-A8, ensuring continuous heavy-duty operations

- Control Options: Operator cabin, remote control, or fully automated operation

- Operating Environment: Up to 200°C in local furnace areas with specialized insulation and heat protection

These charging overhead crane specifications can be customized to ensure that every crane can operate safely and efficiently, even in the most demanding steelmaking environments.

Beyond these technical parameters, a range of optional configurations and tailored solutions is available to further enhance safety, automation, and operational efficiency – allowing your crane to perfectly fit your steel plant’s unique needs.

Charging Crane Customization: Optional Features And Configurations

Aicrane charging cranes are not just built to meet standard specifications – they can be fully tailored to your steel plant’s unique operational needs. Optional configurations and custom solutions allow you to optimize safety, efficiency, and automation for your specific furnace layout and production workflow.

Anti-Sway Control Systems for Precise Furnace Charging

Precise handling is critical when lifting heavy scrap or molten metal. Optional anti-sway systems reduce load swing during hoisting and trolley movement, ensuring accurate placement and minimizing the risk of accidents.

Automatic Positioning & PLC Integration in Charging Crane

For steel plants pursuing higher automation, charging cranes can be equipped with automatic positioning systems and PLC-based controls. These features allow cranes to follow pre-set paths with precision, reduce manual intervention, and improve cycle times.

Remote Operation and Monitoring for Enhanced Safety

Optional remote control and monitoring systems enable operators to control the overhead crane from a safe distance, minimizing exposure to high-temperature furnace areas. Real-time data tracking allows plant managers to monitor crane performance, schedule maintenance, and optimize operations.

Heat-Resistant Enhancements for High-Temperature Environments

For operations near extremely high temperatures, additional thermal insulation, heat shields, and cooling systems can be integrated. These enhancements protect electrical and mechanical components, ensuring consistent performance in harsh furnace conditions.

Customized Hooks, Grabs, and Ladle Attachments for Charging Crane

Different furnace types and material handling needs require specialized lifting attachments. Aicrane provides custom hooks, grabs, and ladle adapters to match your specific scrap buckets, ladles, or furnace charging systems.

Safety and Alarm Systems for Safe Charging Crane Operations

Optional overload protection, collision avoidance, emergency braking, and temperature alarms provide additional layers of operational safety. These systems are especially important for high-capacity cranes operating in busy steel plant environments.

With these optional features and custom configurations, every Aicrane charging crane can be adapted to deliver maximum performance, safety, and efficiency, fully aligned with your steel plant’s workflow and production goals.

Applications of Aicrane Charging Crane in Steelmaking

Our charging cranes are essential for efficient and safe material handling in steel plants. Designed to operate under extreme temperatures and heavy loads, they play a key role in feeding scrap, hot metal, and other raw materials into furnaces with precision and reliability.

Electric Arc Furnace (EAF) Operations

In EAF steelmaking, steel mill charging cranes lift and place scrap metal and alloy additions into the furnace with speed and accuracy. By streamlining the charging process, they help reduce cycle times and improve overall furnace productivity.

Induction Furnace Charging

For induction furnaces, cranes handle smaller batches of metal, providing controlled and precise material placement. This ensures smooth workflow even in compact, high-temperature environments.

Basic Oxygen Furnace (BOF) Applications

In BOF operations, charging overhead cranes efficiently supply hot metal, scrap, and fluxes. Customized attachments allow materials to be delivered exactly where needed, supporting continuous high-frequency lifting.

Auxiliary Material Handling

Beyond furnace charging, these cranes can move ladles, transfer materials between storage areas and furnaces, and integrate with other plant systems. Their adaptability ensures seamless workflow integration and reduced downtime.

By deploying Aicrane charging cranes across various furnace types and material handling tasks, steel plants can achieve faster, safer, and more reliable operations. In addition to charging cranes, a variety of other specialized steel mill cranes are essential in steel production, each designed to meet specific handling requirements and support efficient plant workflow.

Beyond Charging Crane: Other Essential Cranes in Steel Plants

While charging cranes play a central role in feeding furnaces, steel production requires a variety of specialized overhead cranes to handle materials throughout the workflow. Each crane type is designed for specific tasks, ensuring efficient, safe, and continuous operations from raw materials to finished products.

Scrap Handling Crane

Scrap handling cranes are deployed at the initial stage of the steelmaking process to move scrap metal, iron ore, and fluxes from storage yards to charging areas or conveyors. These cranes can be equipped with grab buckets for loose scrap or electromagnets for handling metallic pieces, depending on the material type and operational needs.

Ladle Handling Crane

Once molten metal is ready, ladles must be transported safely to casting lines or secondary processing stations. Ladle cranes lift and move molten steel ladles with precision, supporting continuous production.

Slab and Billet Handling Crane

After casting, slabs and billets must be transferred to rolling mills or storage areas for further processing. Slab and billet handling cranes move heavy slabs and billets efficiently between casting, cooling, and rolling lines.

Coil and Plate Handling Crane

At the final production stage, rolled steel coils and plates are handled for storage, shipping, or further processing. Coil and plate handling cranes are equipped with specialized lifting attachments and stable hoisting mechanisms to prevent product deformation, reduce handling time, and support fast material flow.

Together, these cranes complement charging cranes to form a complete material handling system in steel plants, ensuring that every stage – from raw material preparation to finished steel handling – is performed safely, efficiently, and reliably.

To help your steel plant achieve optimal performance and efficiency, Aicrane also offers comprehensive EPC services, providing turnkey solutions from design and manufacturing to installation and commissioning. See the details below.

Aicrane EPC Services: Turnkey Solutions for Steel Plants

Aicrane’s EPC services provide steel plants with a complete, turnkey material handling and production solution. Beyond steel mill cranes, our EPC offering includes steel structure factory construction, ensuring that the final delivery to the customer is a fully operational, ready-to-use industrial park equipped for steel production.

Engineering and Design: Customized Layouts for Maximum Efficiency

Every project begins with a comprehensive assessment of your plant’s layout, material flow, and production needs. Our engineer teams design not only charging cranes and other steel plant cranes but also the steel structure buildings and infrastructure, optimizing space, workflow, and operational efficiency.

Manufacturing and Construction: Durable Cranes & Robust Steel Structures

Steel plant cranes are manufactured with high-quality materials, while steel structure workshops, warehouses, and auxiliary buildings are fabricated and erected according to strict quality standards. This ensures both durable equipment and robust plant infrastructure.

Turnkey Installation and Commissioning: Fully Operational from Day One

Aicrane oversees the full installation of steel plant cranes, steel structures, and auxiliary systems, commissioning the plant to ensure it is fully functional and ready for production. Clients receive a complete industrial park where all systems are integrated and operational from day one.

Maintenance and Long-Term Support: Keep Your Steel Plant Running Smoothly

Beyond delivery, Aicrane provides ongoing maintenance, inspection, and technical support for cranes and plant infrastructure. This guarantees continuous, reliable operations and minimizes unexpected downtime.

By combining charging cranes, other specialized cranes, and comprehensive EPC services, Aicrane delivers a complete steel production solution – from material handling to infrastructure – ensuring that your plant is safe, efficient, and ready for immediate operation. Get in touch with our experts today and start building your high-efficiency steel plant with Aicrane.