Smarter Container Handling, 30% More Efficiency With Custom Container Gantry Crane

- Strategic Partner of Global Fortune 500 Companies

- Trusted by 1,000+ Customers Worldwide

In the fast-moving world of ports, terminals, and logistics yards, every second counts. Are you losing time and money due to outdated or inefficient container handling equipment? Whether you’re struggling with limited yard space, rising labor costs, or increasing cargo volumes, the right container gantry crane can transform your operations. At Aicrane, we engineer smart, customized container handling solutions to maximize efficiency, minimize downtime, and give you a competitive edge in your industry.

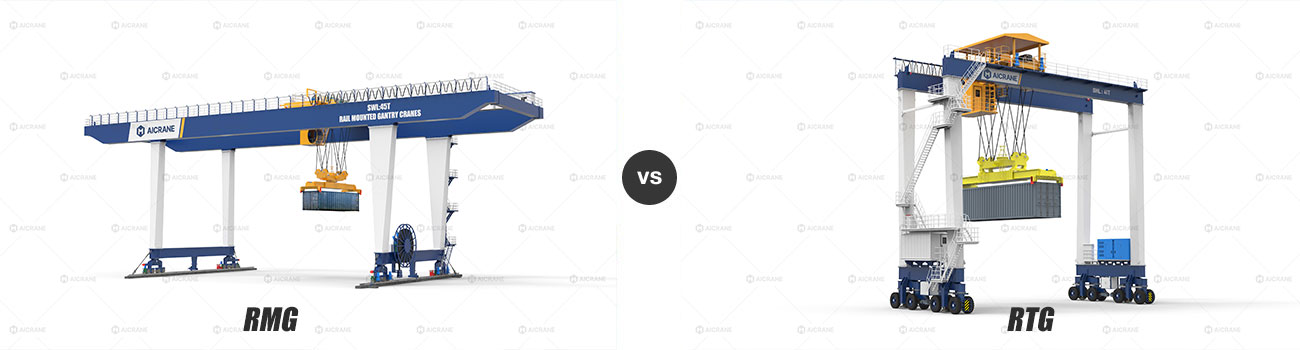

Explore Our Container Gantry Crane Types

Choosing the right crane type is one of the most important decisions you’ll make for your container handling operation. Each environment – whether it’s a port terminal, rail yard, or inland container depot – has its own challenges. Aicrane offers two types of container cranes, each designed to meet different container handling needs:

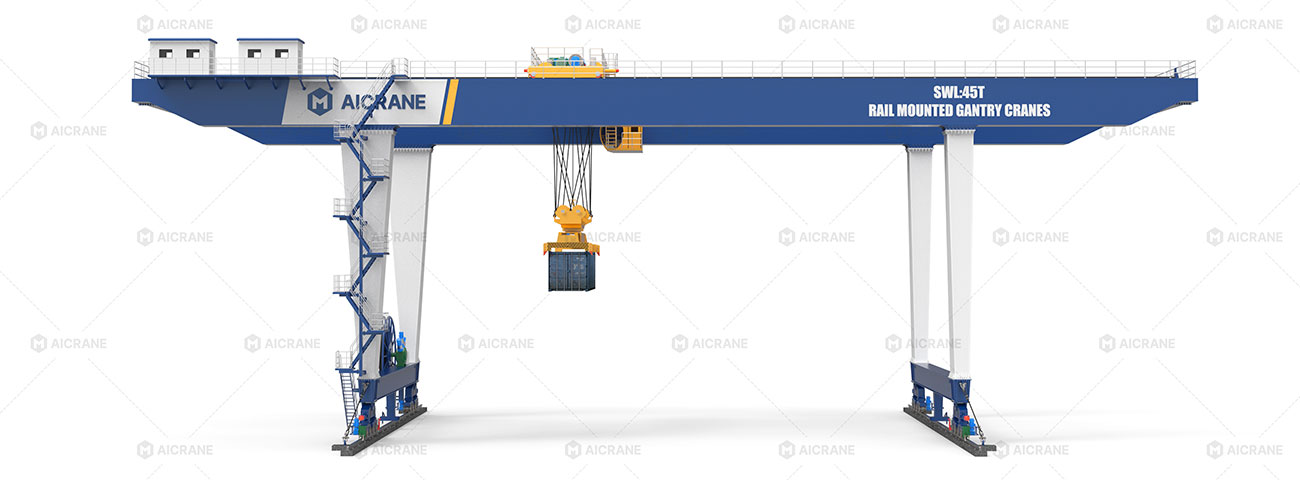

RMG Container Crane – Precision and High Throughput

Rail mounted container gantry cranes run on fixed rails, offering high lifting speeds, accurate container positioning, and exceptional stacking performance. These RMG cranes are ideal for large-volume operations where containers are moved between railcars and stacks with minimal deviation.

Technical Specifications:

- Lifting capacity: 30t, 35t, 40.5t, 45t, 50t (customizable)

- Span: 18-35m (customizable)

- Lifting height: 12.3-21m (customizable)

- Work duty: A6-A8

Key Advantages:

- Stable, high-speed container transfer

- Ideal for automated container yards

- Low operating cost once installed

- High stacking capacity and span options

RTG Container Crane – Mobility and Flexibility

Rubber tyred container gantry cranes move freely on rubber tires, making them perfect for operations that require flexible container stacking without fixed rail constraints. These RTG cranes are especially useful in yards with changing layouts or where expansion is planned.

Technical Specifications:

- Lifting capacity: 30t, 35t, 40.5t, 45t, 50t (customizable)

- Span: 18-35m (customizable)

- Lifting height: 12.3-21m (customizable)

- Work duty: A6-A8

Key Advantages:

- Excellent maneuverability and flexibility

- No need for rail infrastructure

- Easily relocated between work zones

- Available in diesel, electric, or hybrid power options

Both RMG and RTG container gantry crane models are proven solutions for efficient container handling – but their performance varies depending on your specific operation, layout, and future expansion plans.

To help you make the right decision, let’s take a closer look at how these two container crane types compare in key areas like mobility, installation requirements, efficiency, and cost.

RMG VS. RTG: Which Crane Suits Your Container Handling Operation Better?

Choosing between a rail mounted gantry crane and a rubber tyred gantry crane for port, railway terminals and logistics hubs comes down to understanding your site’s needs and long-term operational goals. Here’s a head-to-head comparison to guide your decision:

| Feature | RMG Container Crane | RTG Container Crane |

|---|---|---|

| Mobility | Fixed to rails - limited to a predefined path | Highly mobile – can travel across different yard zones |

| Infrastructure Requirement | Requires rail track and civil works | No fixed rail – simpler foundation requirements |

| Precision Handling | Excellent for automated and high-density stacking | Manual or semi-automated; suitable for lower density |

| Energy Supply Options | Powered by cable reels or busbars | Diesel, electric, or hybrid options available |

| Installation Time | Longer, due to rail and civil works | Shorter and more flexible installation process |

| Ideal Application | Port terminals, rail yards, large-scale fixed facilities | Container yards, smaller ports, flexible or growing sites |

| Operating Cost | Lower long-term, especially for automated operations | Moderate to high, depending on power system |

| Automation Compatibility | Well-suited for full automation and remote control | Limited or partial automation features |

Key Decision Factors to Consider

To help you choose the right container gantry crane type, ask yourself these questions:

Do you have a fixed layout or need flexibility?

If your site is structured and container movement follows a fixed route, a rail mounted gantry (RMG) crane is the better fit.

For changing yard layouts or operations that require relocation, a rubber tyred container mobile crane offers greater flexibility.

Is your priority automation or mobility?

RMG container handling gantry cranes are built for automation, ideal for smart terminals and high-efficiency operations.

RTG container crane for sale is better suited when mobility and adaptability are more important than full automation.

What is your budget for infrastructure?

Rubber tyre container gantry cranes need minimal site preparation and no rail installation, making them more cost-effective to deploy.

RMG container gantry cranes involve higher initial civil work but provide better long-term value through lower operating and maintenance costs.

How high is your container handling volume?

If your operation handles large volumes continuously, RMG container cranes offer faster cycle times and better precision.

For moderate volumes or varied workload, RTG container cranes offer the flexibility to move where needed.

Is stable power supply available at your site?

If grid power is stable, rail mounted container gantry cranes are highly efficient.

If your site lacks reliable power or needs off-grid operation, rubber tyred container gantry crane rtg with diesel or hybrid systems is a better option.

Do you plan to scale or expand in the future?

If your yard will grow or change layout, rubber tyred container gantry cranes can adapt without reworking infrastructure.

For permanent, high-density stacking zones, RMG container gantry cranes are ideal.

Whether you need high-capacity rail-based precision or flexible yard coverage, Aicrane has the experience and technology to design an overhead container gantry crane system that fits your goals.

In the next section, we’ll show you how to maximize container handling efficiency through advanced features, smart control systems, and innovative container crane design – no matter which type you choose.

Smarter, Safer, More Efficient: Advanced Container Crane Technology

No matter whether you choose an RMG or RTG gantry crane for container handling, you can dramatically improve your container handling performance by incorporating advanced features and smart engineering. At Aicrane, we offer a range of advanced technologies designed to help you move containers smarter, safer, and more efficiently.

Anti-Sway Technology for More Precise, Safer Container Handling

Our anti-sway systems use sensors and real-time control to reduce load swing during travel and hoisting, resulting in:

- Faster cycle times

- Improved safety

- Easier load alignment

Intelligent Positioning Systems for Faster and More Accurate Operations

Smart positioning systems allow operators to automatically or semi-automatically align containers with trucks, railcars, or stacks. Features include:

- Auto-trolley centering

- Precise container landing assistance

- GPS-based tracking (for RTG mobile container crane)

Dual Trolley & Twin-Lift Designs for Higher Throughput and Efficiency

Need to increase throughput? A dual-trolley or twin-lift system allows the shipping container gantry to handle two containers at once or operate simultaneously across different positions, improving:

- Container flow

- Yard productivity

- Equipment utilization rate

Remote Operation and Diagnostics for Reduced Downtime

Our intermodal container cranes support optional remote control cabins and real-time monitoring systems, enabling:

- Safer operation from centralized control rooms

- Quick response to faults or alerts

- Reduced need for on-site personnel in hazardous zones

Energy-Efficient Drives for Lower Operating Costs and Sustainability

We offer gantry crane lifting container with regenerative braking, variable frequency drives (VFDs), and hybrid or fully electric options to help you:

- Save energy

- Lower operating costs

- Reduce emissions

Modular Design for Fast Assembly and Relocation

Our shipping container gantry crane for sale is designed with modular components to:

- Shorten installation time

- Simplify transport logistics

- Allow easier future relocation or reconfiguration

Collision Avoidance Systems for Safer Multi-Crane Operations

Equipped with radar, laser, or video sensors, our container gantry cranes detect nearby obstacles or other equipment and adjust movement automatically to avoid accidents – especially useful when multiple cranes work in the same area.

Integrated Weighing Systems for Compliance and Load Accuracy

Built-in weighing systems allow operators to record container weight during lifting, meeting global shipping regulations (like SOLAS) and improving yard management.

By combining the right gantry crane for container with these advanced features, you gain not only better container handling performance but also greater safety, lower costs, and future-proof capability.

Next, we’ll show you how real customers worldwide are using these technologies to solve problems, improve efficiency, and scale their operations.

Trusted by Over 1,000 Customers Worldwide: Aicrane Container Crane Projects

With over 1,000 customers across ports, terminals, rail yards, and container depots, our gantry container cranes are trusted worldwide to improve efficiency, safety, and long-term value. Below are some of our recent project highlights that show how the right crane system can transform operations on the ground.

Rail Container Yard Boosts Throughput with Customized RMG Gantry Container Crane

Location: Almaty, Kazakhstan

Challenge: A logistics company operating a busy rail container yard needed a high-efficiency container gantry crane to handle a mix of 20ft, 40ft, and 45ft containers. Their yard processes 100-120 containers per day and required a solution that could deliver fast, continuous operation.

Solution: We supplied a 45 ton rail mounted gantry (RMG) cranes with a 32-meter span, 12.5-meter lifting height, 8m and 5.5m cantilevers for flexible loading/unloading on both sides, a telescopic spreader to handle 20ft, 40ft, and 45ft containers efficiently without manual adjustment, and intelligent anti-sway system for stable lifting and precise positioning.

Results:

- Container handling efficiency increased by 35%

- Consistent daily handling of 100-120 containers with high uptime and minimal delays

- Faster container turnover, thanks to the automatic adjustment of the telescopic spreader

More Container Gantry Crane Projects

How Much Does a Container Gantry Crane Cost?

After learning how container gantry cranes have helped companies around the world improve their operations, you’re probably wondering: What’s the actual cost of investing in one for your business? Below is an overview of the typical price range and the key factors that affect the final cost.

Container Gantry Crane Price Range

The container gantry crane price depends on several key factors, including crane type, lifting capacity, span, lifting height, working duty, and level of customization. Below is a general reference price range for rail mounted models:

RMG Container Crane Price (capacity 30-50 ton, span 22-32m): USD $270,000 – USD $480,000 and beyond

Please note that these prices are for reference only. The final cost of a container gantry crane is determined by a customized technical solution based on your actual working conditions, site layout, and operational needs.

What Affects the Cost of a Container Gantry Crane?

Load Capacity – More Lifting Power Means Higher Cost

Higher container gantry crane capacity (e.g., 45 tons vs. 30 tons) requires stronger structural components, larger motors, and reinforced hoisting systems, all of which increase overall cost.

Span Length – Wider Cranes Require More Materials and Engineering

Longer span means more steel, more precise structural design, and higher wheel loads – leading to increased manufacturing and installation costs.

Lifting Height – Higher Stacking Means Heavier Structures

A greater lifting height requires longer hoist ropes, larger drums, and stronger masts or legs, especially when stacking containers in multiple layers.

Container Types and Sizes – Spreader Adaptation Adds Cost

If you need to handle multiple container types – such as 20ft, 40ft, and 45ft containers, you’ll require a telescopic spreader or automatic spreader adjustment system. This customization adds to the base cost, but improves flexibility and efficiency.

Operating Speed – Higher Travel and Hoist Speeds Demand Better Drives

Higher operational speed (trolley travel, crane travel, hoisting speed) requires more powerful motors, precision control systems, and larger gearboxes – all of which impact pricing.

Duty Cycle – Continuous Operation Needs Heavy-Duty Components

Higher duty classes (A6 or above) demand premium-quality brakes, motors, gearboxes, and cooling systems, which add significantly to container crane cost.

Control Method – Automation and Remote Control Add Value and Cost

Adding a cabin, wireless remote, or smart auto-control increases safety and efficiency – but also raises system complexity and price.

Smart Technologies – Advanced Features Raise the Bar and the Budget

Features like anti-sway, auto-positioning, GPS tracking, and container weighing systems enhance performance – but increase overall crane value and investment.

Installation and Commissioning – Service Scope Impacts Cost

Some projects require full service, including foundation design, local assembly, and on-site testing. More comprehensive support equals a higher project quote – but better long-term outcomes.

Whether you need a mobile solution for a flexible yard or a high-speed, rail-mounted crane for a busy terminal, we can help you find the right balance between performance and budget.

Would you like to learn more about how Aicrane supports your project – from planning to after-sales service? We’ll cover that next.

Aicrane: Your Trusted Partner in Container Gantry Crane Solutions

Selecting the right gantry crane for shipping container is more than choosing equipment – it’s choosing a long-term partner for your operation. As one of the trusted container crane manufacturers, Aicrane has earned the confidence of over 1,000 customers worldwide for their container handling projects. Here’s why so many choose us for reliable, customized solutions.

Pre-Sales Consultation & Technical Design

We begin with a detailed needs analysis based on your site conditions and operational goals:

- Yard layout review and lifting path analysis

- Crane type selection (RMG or RTG)

- Span, cantilever, and lifting height optimization

- Throughput and work duty evaluation

- Optional features recommendation (anti-sway, automation, spreader type)

You’ll receive a customized technical proposal with drawings, configuration specs, and estimated costs.

Professional Manufacturing & Quality Assurance

Once your order is confirmed, our modern production facility ensures:

- Use of high-quality structural steel and branded electrical components

- Strict adherence to ISO, FEM, and GB standards

- Precision welding, machining, and assembly processes

- Full factory testing of mechanical and electrical systems

- FAT (Factory Acceptance Testing) and inspection reports before shipment

Every crane is built to withstand demanding container operations – day in, day out.

Delivery & Logistics Coordination

We manage the full shipping process:

- Efficient packing and labeling of crane components

- Worldwide sea freight and inland delivery arrangements

- Customs clearance support and documentation

- Real-time logistics tracking and updates

Whether your terminal is in a remote rail hub or a coastal port, we ensure on-time and damage-free delivery.

Installation & After-Sales Service

We offer flexible installation options and long-term support based on your project needs:

- Online guidance with detailed manuals, video instructions, and remote engineer support

- On-site supervision by Aicrane technicians

- Operator training to ensure safe and efficient use from Day 1

- Fast spare parts supply from our dedicated warehouse

- Periodic technical check-ups and service visits upon request

Choosing Aicrane as your trusted container gantry crane manufacturer means opting for quality, expertise, and unwavering support. If you are looking for a custom solution, Aicrane is here to help. Contact us today to learn more about our products and services and to discuss your specific needs!

FAQs about Container Gantry Cranes

What Is a Container Gantry Crane?

How Do Container Cranes Work?

What Safety Features Do Container Handling Cranes Have?

Can container gantry cranes be automated or remote-controlled?

How to Choose the Right Container Gantry Crane Capacity?

How Is the Gantry Container Crane Span and Lifting Height Determined?

Can Your Container Gantry Cranes Be Customized?

How Do Container Terminal Cranes Handle Different Container Sizes?

How Can Container Crane Automation Improve Container Yard Efficiency?

Future Trends: Green, Automated & AI-Driven Container Gantry Cranes

As global logistics and port transportation evolve, so do the demands placed on container lifting gantry cranes. Today’s buyers aren’t just looking for equipment that works – they want cranes that are smarter, cleaner, and ready for the future. Here are the key trends shaping the next generation of gantry crane for container handling, and how your investment today can prepare you for tomorrow.

AI & IoT Are Powering Predictive Maintenance and Real-Time Monitoring

Using IoT sensors and AI algorithms, operators can monitor crane health in real time, predict issues before they occur, and optimize maintenance schedules.

Aicrane can equip your container lifting crane with:

- Condition monitoring sensors

- Remote diagnostic systems

- Smart dashboards for predictive maintenance insights

Automation Is Becoming the New Standard

Automation isn’t just for mega ports anymore. Even mid-size terminals are adopting semi or fully automated container gantry cranes to improve throughput, reduce labor dependency, and increase precision.

Key developments:

- Smart anti-sway systems

- Automated container positioning

- Integration with terminal operating systems (TOS)

- Remote operation cabins or unmanned operation

Green Port Development Is Driving Electric and Hybrid Solutions

With increasing pressure to reduce carbon emissions, especially in ports and rail terminals, more operators are replacing diesel-powered cranes with fully electric or hybrid RTG/RMG cranes.

Aicrane’s solution:

We offer energy-efficient electric RTG and RMG container cranes, as well as hybrid drive options with regenerative braking and smart power management.

By aligning your investment with these trends, you’re not only operational today – you’re future-proofing your terminal for the logistics demands of tomorrow.

Ready to upgrade your container handling operations? Contact Aicrane today for a personalized consultation and discover how our cutting-edge container gantry cranes can help you lead in efficiency, sustainability, and automation.