Our railway gantry cranes provide efficient, reliable lifting and handling solutions in railway operations, improving efficiency and productivity in railway logistics. Available in various types and configurations, they can be custom-designed to meet your specific transportation and logistics requirements.

Different Types of Gantry Cranes For Rail Yards

In rail yards, various types of gantry cranes are employed based on specific lifting demands and operational requirements. Single and double girder gantry cranes are commonly used for handling a wide range of general cargo, while rail mounted gantry cranes are specifically designed for stacking and transporting containers within the yard. For operations requiring greater flexibility and mobility, rubber tyred gantry cranes offer the versatility needed to move efficiently across different areas of the railway yard. Explore the details of our different railway gantry cranes for sale below.

Lifting capacity:30-50t

Span:18-35m

Lifting height:12.3-21m

Custom design available

Lifting capacity:10-800t

Span:5-35m

Lifting height:6-18m

Custom design available

Lifting capacity:3.2-20t

Span:8-35m

Lifting height:6-12m

Custom design available

Lifting capacity:5-500t

Span:18-35m

Lifting height:6-18m

Custom design available

How Gantry Cranes Supercharge Railway Operations: Discover Their Common Uses

Our railway gantry crane for sale plays a vital role in railway operations, offering high efficiency and versatility for handling various types of loads. The primary functions include handling containers, loading, and unloading cargo, helping streamline logistics processes at railway terminals.

Container Handling

One of the primary functions of railway gantry cranes is container handling. Rail yards require specialized gantry cranes to lift and move containers with precision and speed. These container handling gantry cranes can handle a variety of container sizes, such as 20-foot, 40-foot, and 45-foot containers, making them essential for efficient freight operations.

45 Ton RMG Crane Enhances Railway Container Handling Efficiency in Kazakhstan

A logistics company operating at the Almaty railway container terminal in Kazakhstan required a robust and efficient solution specifically tailored for railway yard container handling.

To streamline the transfer and stacking of containers directly from trains, they chose a 45-ton RMG crane designed for demanding railway environments. This crane can efficiently lift and transfer between 100 to 120 containers daily.

- Span: 32 meters

- Lifting height: 12.5 meters

- Work duty: A6

- Cantilever length: 8 meters and 5.5 meters

32 Ton Double Girder Gantry Crane for Railway Container Operations in Kazakhstan

At a railway logistics hub in Atyrau, Kazakhstan, a 32-ton double girder gantry crane is deployed to handle container loading and unloading from freight trains. The crane’s configuration suits the railway yard’s spatial and operational demands, ensuring seamless integration into the rail-based logistics workflow..

- Crane capacity: 32 tons

- Span: 30 meters

- Lifting height: 13 meters

60 Ton Double Girder Gantry Crane Supports Railway Container Handling in Chile

In Chile, a logistics company relies on 60-ton double girder gantry cranes for intensive container operations at their railway freight terminal. With substantial lifting capacity, these cranes efficiently manage heavy containers arriving and departing via rail, guaranteeing reliable performance under heavy railway cargo handling demands.

General Cargo Handling

Another key application of gantry cranes in railway operations is the loading and unloading of railcars. These cranes can lift various materials, from steel coils and concrete products to general cargo, ensuring smooth and efficient operations across railway terminals.

20 Ton Rail Yard Crane for Loading And Unloading Steel Products

A client utilizing a 20-ton single girder gantry crane for loading and unloading steel and concrete products along a railway required a specialized design capable of operating in extremely cold temperatures, down to -40℃. This crane meets the challenge, offering reliable performance in harsh environments.

- Crane capacity: 20 tons

- Span: 32 meters

- Lifting height: 15.6 meters

- Work duty: A3

- Cantilever length: 8 meters and 14 meters

- Control methods: Cabin control and remote control

20 Ton Double Girder Railway Gantry Crane for Loading And Unloading Steel Coils in Uzbekistan

A client company in Uzbekistan uses a 20-ton double girder gantry crane for loading and unloading steel coils and other heavy materials onto trains.

- Crane capacity: 20 tons

- Span: 20 meters

- Lifting height: 12 meters

- Cantilever length: 7 meters

- Work duty: A5

- Control methods: Pendant control and remote control

10 Ton Gantry Crane for Loading And Unloading General Cargo in Uzbekistan

Another customer in Uzbekistan relies on a 10 ton single girder gantry crane for loading and unloading cargo onto trains. This crane is designed with a single cantilever, which facilitates easy access for loading and unloading on the cantilever side, enhancing operational flexibility.

Our solutions go beyond these applications. Whether it’s rail freight, infrastructure construction, or intermodal operations, we offer customized railway gantry crane solutions to boost your efficiency. Contact us today to find the right solution for your railway needs! You can also read on to see how we custom a solution for your project.

Custom Railway Gantry Crane Solutions

At Aicrane, we specialize in the custom design and manufacturing of railway gantry cranes, tailored to meet the specific needs of rail yards, freight terminals, and intermodal handling facilities.

Fully Customized Specifications for Your Rail Yard Needs

All of our railway gantry cranes are 100% customizable, engineered to align with the unique operating conditions and logistical challenges at your site. Whether you’re handling containers, steel coils, bulk cargo, or large machinery, our solutions are built for reliable performance.

We tailor the following key specifications and parameters to meet your needs:

- Rail Gauge Matching: Custom spans adaptable to single or multiple rail tracks.

- Lifting Height: Designed to accommodate container stacking heights or train car clearance requirements.

- Lifting Capacity: Custom design to suit various cargo weights and handling volumes.

- Cantilever Configuration: Single or double cantilever gantry cranes for extended reach and improved material access.

- Duty Classification: Work classes such as A5, A6, and A7 available depending on operation frequency and load cycles.

Each system is built to ensure maximum efficiency in container and cargo handling while adapting seamlessly to site limitations and rail infrastructure.

Custom Safety Features Designed for Complex Rail Environments

Every rail yard gantry crane we design is equipped with comprehensive safety features to ensure safe operation in busy rail yard environments:

- Overload protection systems to prevent excessive lifting beyond rated capacity

- Storm lock and rail clamp devices to secure the crane during severe weather or when parked

- Travel limit switches and buffers to avoid over-travel and mechanical collision

- Emergency stop mechanisms for immediate response during abnormal situations

- Anti-collision sensors and zone limiters to detect obstacles and restrict crane movement within safe zones

- Intelligent monitoring system using visual recognition to make crane operation visualization to ensure safe and stable equipment performance.

We also offer special structural designs for extreme climates, including anti-corrosion finishes, cold-weather adaptations, and wind-resistant gantry frames.

In-House Experts Delivering Custom Railway Lifting Solutions

Our dedicated crane engineering team comprises solution engineers and electrical specialists who work closely with clients to develop precise, cost-effective solutions. Our design process includes:

- On-Site Evaluation: Our engineers will assess site layout, track specifications, environmental conditions, and logistics flow.

- Structural Analysis & Load Calculations: All cranes are designed in compliance with international standards, with detailed structural load verifications and fatigue life analysis.

- Layout Optimization: We use 2D and 3D modeling tools to simulate crane movement and working envelopes, ensuring zero conflicts with infrastructure or cargo traffic paths.

- Smart Crane Integration: Advanced features such as anti-sway systems, remote control, automatic positioning, and container identification systems can be integrated to enhance safety and efficiency.

Ready to upgrade your rail operation? Let us help you build a more productive, safe, and future-ready railway cargo handling system. Contact Aicrane today to receive a free customized design proposal, technical consultation, or detailed quote.

How Much Is a Railway Gantry Crane?

Each railway operation has its own specific requirements, which means the crane solutions needed can vary greatly. As a result, the railway gantry crane price is not one-size-fits-all. It is influenced by numerous factors, including the type of crane, its lifting capacity, span, lifting height, work duty, customization level, and the complexity of the application environment.

To help you gain a general understanding of our railway gantry crane pricing, we’ve provided a reference price list for different models and configurations below.

Railway Rail Mounted Gantry Crane Prices

| Capacity | Span | Lifting Height | Price (USD) |

|---|---|---|---|

| RMG 30 Ton | 22-32m | 12.3-21m | $264,000-$338,000 |

| RMG 40 Ton | 22-32m | 12.3-21m | $352,000-$412,000 |

| RMG 50 Ton | 22-32m | 12.3-21m | $411,000-$471,000 |

Double Girder Railway Gantry Crane Prices

| Capacity | Span | Lifting Height | Price (USD) |

|---|---|---|---|

| Double Girder 10 Ton | 18-35m | 6-18m | $44,000-$110,000+ |

| Double Girder 20 Ton | 18-35m | 6-18m | $73,000-$147,000+ |

| Double Girder 32 Ton | 18-35m | 6-18m | $88,000-$176,000+ |

| Double Girder 50 Ton | 18-35m | 6-18m | $110,000-$206,000+ |

Single Girder Railway Gantry Crane Prices

| Capacity | Span | Lifting Height | Price (USD) |

|---|---|---|---|

| Single Girder 5 Ton | 10.5-31.5m | 6-12m | $14,000-$35,000+ |

| Single Girder 10 Ton | 10.5-31.5m | 6-12m | $19,000-$43,000+ |

| Single Girder 20 Ton | 10.5-31.5m | 6-12m | $29,000-$62,000+ |

It’s important to note that the railroad gantry crane pricing provided here is a general estimate, and it is advisable to consult with Aicrane professionals to obtain accurate pricing information tailored to your requirements. We can provide detailed quotations based on your specific needs.

Discover the Different Control Solutions for Railway Gantry Cranes

To help our railway customers optimize efficiency, safety, and productivity, we offer a range of control systems tailored to various application scenarios.

Pendant Control – Simple, Cost-Effective, and Reliable

Pendant control remains a practical solution for small to medium-sized rail yard gantry cranes, especially in maintenance yards or depots. The operator uses a handheld controller connected via cable to perform basic crane functions. It’s a reliable and cost-effective option when proximity to the load is beneficial and space is limited.

Wireless Remote Control – Improved Visibility and Safety

For more flexible operation, our wireless remote control systems allow operators to manage crane functions from a distance. This improves load visibility and keeps personnel out of potentially hazardous areas – particularly useful in busy or large rail yards where multiple operations take place simultaneously.

Cabin Control – For Heavy-Duty, Continuous Railway Operations

For railway yard heavy duty gantry cranes handling large volumes of cargo or materials, cabin control is the ideal solution. The operator works from a dedicated cabin equipped with ergonomic joysticks, monitoring systems, and full-function panels, ensuring smooth and precise control even during long shifts and challenging operations.

Intelligent Control System – Enhancing Railway Efficiency Through Smart Technology

Our intelligent control system is designed to meet the high efficiency and precision requirements of modern railway operations. This advanced system combines PLC automation, variable frequency drives (VFDs), and 5G communication technology to deliver smart, responsive crane performance. With real-time system monitoring and predictive maintenance capabilities, it significantly reduces downtime and enhances efficiency and safety.

Key Factors to Consider When Buying a Railway Yard Gantry Crane

When selecting a gantry crane for railway yard, several factors need to be considered to ensure optimal performance and efficiency. Here are some key factors to consider when buying a railroad gantry crane:

Rail Yard Layout and Space

Evaluate the layout and available space in the railway yard. Determine the required span of the railway crane to cover the number of tracks and storage areas effectively. Consider any height restrictions or obstacles that may impact the crane’s movement and operation.

Lifting Capacity

Determine the maximum weight of the containers or cargo that will be handled in the railway operation. Select a railroad gantry crane with a lifting capacity that meets or exceeds the heaviest loads expected. Consider the future growth of cargo volumes to ensure the crane can handle potential increases in weight.

Rail-mounted or Rubber-Tired

Decide whether a rail-mounted gantry crane or a rubber-tired gantry crane is more suitable for the railway freight yard. RMGs are ideal for yards with fixed track layouts, while rubber wheeled gantry cranes offer flexibility and maneuverability in cargo handling. Also consider the terrain and ground conditions when deciding between rail or rubber-tired operation.

Load Type

Evaluate the types of cargo typically handled in your railway yard – such as containers, general cargo, bulk materials, and more. The gantry crane you select should be capable of accommodating the size, shape, and weight of these various loads.

Operational Requirements

Assess the specific operational requirements of the railway yard. Consider factors such as the expected container throughput, productivity targets, and any specialized handling needs. Choose a crane that can meet the operational demands, taking into account factors like lifting speed, trolley movement, and automation capabilities.

Safety Features

Prioritize safety features when selecting a railroad crane. Look for features such as anti-collision systems, load monitoring sensors, emergency stop mechanisms, and operator safety controls.

Maintenance and Serviceability

Consider the ease of maintenance and serviceability of the gantry crane. Look for features such as accessible components, availability of spare parts, and reliable technical support from the railway gantry crane manufacturer or supplier. Assess the crane’s reliability and maintenance requirements to minimize downtime.

Cost and Budget

Evaluate your initial cost, including installation, as well as the long-term operating costs associated with the railway gantry crane. Consider the crane’s energy efficiency, maintenance costs, and potential upgrades or modifications required in the future. Balance the upfront investment with the expected return on investment and the crane’s lifespan.

By considering these factors, you can select a crane that aligns with your lifting and handling needs in railway logistics operations. You can also consult with experienced railway gantry crane manufacturers or suppliers who can provide valuable guidance throughout the selection process.

Aicrane One-Stop Service for Railway Industry: From Consultation to Lifecycle Support

Aicrane offers a comprehensive one-stop service tailored specifically for railway applications, ensuring that rail yard gantry crane solutions are delivered with precision, speed, and long-term support. Aicrane service covers every stage – from consultation to after-sales – helping clients streamline procurement, installation, and operational performance.

Expert Consultation and Project Assessment

The process begins with a professional consultation focused on the unique requirements of railway operations.

- Site analysis for rail yards: Aicrane engineers conduct thorough site assessments to understand track layouts, cargo types (e.g., containers, steel coils, rail segments), and operational constraints.

- Operational needs evaluation: We engage with clients to identify specific goals such as load capacity, frequency of use, type of rail cargo handling, and environmental conditions.

- Customized design options: We offer tailored configurations for rail gantry cranes – adjustable spans, dual lifting trolleys, extended cantilevers, and various control modes – to fit specialized railway scenarios.

Tailored Crane System Design for Railway Applications

Once the consultation is complete, our engineering team develops a bespoke crane design optimized for the client’s operational goals:

- Precise technical drawings: Layouts consider track positioning, cargo flow, wind load conditions, and space limitations at railway sites.

- Application-specific engineering: Whether for container handling, flatcar unloading, or transferring heavy equipment, the crane is engineered to maximize productivity.

- Efficiency & lifecycle cost analysis: We focus on delivering cost-effective solutions without compromising durability, safety, or performance under high-cycle workloads.

Manufacturing with High Standards in Mind

With the design finalized, Aicrane manages the full manufacturing and procurement process with quality and precision:

- High-quality materials: We ensure that the crane is manufactured using high-quality steel and other durable materials to guarantee long-term reliability and safety.

- Precision manufacturing: The manufacturing process follows strict quality control protocols, utilizing advanced technology to meet exact specifications.

Logistics and Timely Delivery to Rail Sites

Once the crane is completed, we take care of the logistics and delivery to ensure that the equipment arrives safely and on time. Services include:

- Pre-delivery checks: Before shipping, our cranes undergo thorough quality inspections and testing to verify that they meet performance and safety standards.

- Global shipping: We coordinate international shipping and handles all necessary documentation, customs clearances, and transportation.

- Timely delivery: Our logistics planning ensures delivery aligns with the railway project schedule, reducing costly downtime.

Installation & Commissioning for Rail Environments

We provide complete support during crane installation at the client’s railway site:

- On-site or remote guidance: Our expert technicians provide on-site installation assistance or remote guidance through video calls and other digital tools to ensure the crane is installed correctly.

- Testing and commissioning: After gantry crane installation, we perform operational tests to ensure the crane functions as expected and complies with all safety standards.

- Training for operators: Our company also provides training to crane operators and maintenance personnel, ensuring safe and competent equipment handling in the rail yard environment.

Comprehensive After-Sales Support for Railway Operators

Post-installation, Aicrane continues to support railway clients with a robust after-sales services system:

- Preventive maintenance: We offer maintenance schedules designed for railway duty cycles to prevent downtime and extend service life.

- Spare parts supply: Fast shipping of replacement parts such as wheels, brakes, motors, and control units minimizes interruption to operations.

- 24/7 technical support: Customers can rely on our expert technicians for troubleshooting and support at any time.

Aicrane’s one-stop service for railway gantry cranes is engineered to support the specialized demands of the railway industry. With a focus on customized solutions, technical precision, and lifetime support, we help clients across the globe improve operational efficiency, safety, and cost control in rail-based logistics and material handling.

Let Aicrane be your trusted partner in railway crane solutions – from design to delivery and beyond.

The Future of Railway Gantry Cranes: Industry Outlook and Development Trends

As the global railway industry evolves with increased demand for efficient logistics, urbanization, and infrastructure modernization, railway gantry cranes are becoming increasingly vital. These specialized lifting systems are essential for handling heavy loads with speed, safety, and precision, making them indispensable in modern railway construction, maintenance, and intermodal freight operations.

Global Railway Industry Outlook

The railway sector plays a critical role in global transportation, providing a cost-effective, energy-efficient mode of freight and passenger movement. According to the International Energy Agency (IEA), rail transport accounts for about 6% of freight tonne kilometers and is expected to grow significantly with the push for sustainable transport solutions.

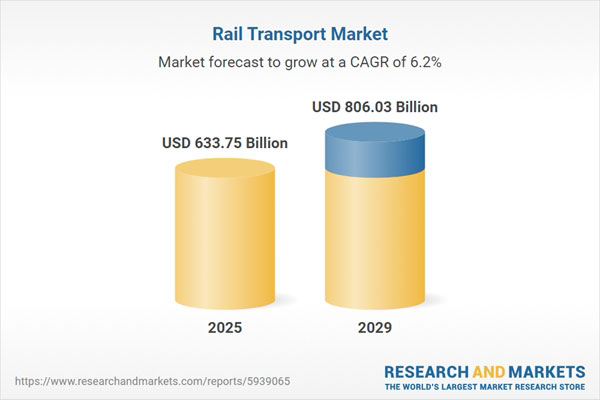

In addition, Rail Transport Market Report by Research and Markets estimates forecasts the rail transport market to grow from $590.5 billion in 2024 to $633.7 billion in 2025, at a CAGR of 7.3%. This expansion during the historical period has been driven by factors such as robust economic growth in emerging markets, the surge in e-commerce, changes in taxation policies, and increased mining activity.

Development Trends in the Railway Sector Impacting Gantry Cranes

- Expansion of Rail Freight Corridors: Rail freight is witnessing renewed focus due to its lower carbon footprint compared to road and air transport. The development of dedicated freight corridors (DFC) – such as India’s ambitious DFC project or China’s Belt and Road Initiative – is fueling the need for robust material handling equipment including railway gantry cranes. These cranes are crucial for efficient container handling and train loading operations along these corridors.

- Modernization and Automation: Railway terminals and maintenance depots are rapidly adopting automation technologies. Integration of smart gantry cranes equipped with sensors, IoT connectivity, and remote-control operation enhances safety and operational efficiency.

- Sustainability and Energy Efficiency: With governments globally enforcing stricter environmental standards, railways are becoming a preferred mode of transport. Gantry cranes themselves are evolving to use electric and hybrid power systems to reduce emissions, aligning with the global push for green logistics.

- Urbanization and Intermodal Transport Growth: Increasing urbanization is driving demand for intermodal transport solutions – where goods are transferred seamlessly between rail, road, and sea transport. Railway gantry cranes serve as pivotal equipment in multimodal terminals, handling containers swiftly to minimize turnaround time and costs.

Challenges and Future Prospects

While the railway gantry crane market is poised for growth, challenges such as high capital investment, technological integration complexities, and maintenance requirements exist. However, continuous innovations in crane design, predictive maintenance using AI, and modular construction techniques are expected to overcome these barriers.

In the future, we anticipate:

- Greater customization of railway gantry cranes to meet specific railway cargo and infrastructure needs.

- Increased adoption of automation and AI for predictive maintenance and operational efficiency.

- Expansion of electric and hybrid railway cranes aligned with sustainability goals.

If you’re looking to enhance your rail operations with reliable, efficient, and cutting-edge railway gantry crane solutions, contact us today. Our expert team is ready to provide customized equipment and support tailored to your unique needs – helping you stay ahead in this dynamic industry. Let’s build the future of rail logistics together!