Aicrane girder overhead crane is one of the most common and versatile lifting solutions in industrial facilities. It uses a bridge girder to carry the hoist and trolley, moving loads safely and efficiently along runway beams. Whether in manufacturing plants, steel workshops, shipyards, or logistics centers, our bridge girder crane plays a critical role in ensuring lifting efficiency and safety.

Different Models of Girder Overhead Cranes

At AICRANE, we offer a complete range of girder bridge cranes designed to meet diverse lifting requirements. Each model features a specialized overhead crane girder design to ensure durability, safety, and performance.

AQ-HD Single Girder Bridge Crane

Structure: Single girder, with a composite welded girder fabricated from steel plates, or sometimes H-beam girder.

Technical Specifications:

- Capacity: 5-20 tons

- Span: 7.5-28.5m

- Lifting height: 6-18m

- Work duty: A5

- Custom designs available

AQ-LD Single Beam Overhead Crane

Structure: Single bridge crane girder, often designed as a composite girder made by welding I-beams with other steel sections or plates.

Technical Specifications:

- Capacity: 5-25 tons

- Span: 7.5-31.5m

- Lifting height: 6-30m

- Work duty: A3, A4

- Custom designs available

AQ-QD Double Girder Overhead Crane

Structure: Overhead crane main girders are box girder structure

Technical Specifications:

- Load capacity: 10-450t

- Span: 10.5-31.5m

- Lifting height: 6-24m

- Work duty: A3-A7

- Custom designs available

AQ-QDX Double Girder Bridge Crane

Structure: Double bridge crane girders, box girder type with advanced design standards.

Technical Specifications:

- Load capacity: 10-320t

- Span: 10.5-31.5m

- Lifting height: 6-24m

- Work duty: A3-A5

- Custom designs available

AQ-NLH Double Girder Bridge Crane

Structure: Double girder configuration, with welded composite girders made from steel plates, or H-beam girders.

Technical Specifications:

- Load capacity: 10-80t

- Span: 10.5-31.5m

- Lifting height: 6-18m

- Work duty: A5

- Custom designs available

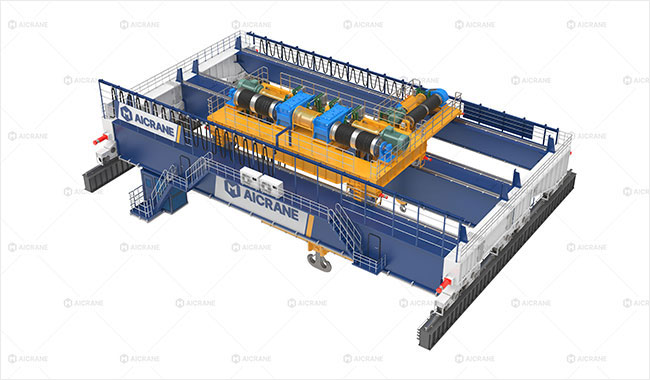

Customized Girder Overhead Crane

AICRANE also provides customized girder overhead cranes for specialized lifting applications, such as:

Double Girder Casting Bridge Crane

Designed for steel foundries and metallurgical applications, this foundry crane features double box girders with reinforced structure.

Three-Girder Forging Bridge Crane

A three-girder design provides enhanced stability and capacity. It is often applied in forging workshops, and the additional girder ensures better load distribution and higher safety margins.

Four-Girder Casting Bridge Crane

This heavy-duty girder bridge crane employs four parallel girders for maximum load-bearing capability. It is used in steel plants, foundries, and other extreme-duty industries for transporting molten metal or oversized components.

Explore more girder overhead crane specifications and models and find the perfect solution for your lifting needs.

Customer Cases & Reviews: Girder Overhead Cranes in Action

AQ-NLH Double Girder Overhead Crane for Machinery Manufacturing in Russia

A Russian machinery manufacturing plant needed a crane for handling large machine components and assemblies with high precision. The project required a reliable crane with a capacity of 64 tons (32+32 tons), a span of 22.5 meters, and a lifting height of 11 meters. After evaluating various solutions, the customer selected the AQ-NLH double girder overhead crane.

Why this type?

- Double girder design provided higher lifting capacity and better stability

- Lightweight box girder structure with high strength

- Frequency conversion control offered smoother operation and reduced mechanical stress

Customer Review – Mr. Ivanov, Plant Director:

“The AQ-NLH 64 ton girder overhead crane has been a great addition to our workshop. It combines strength with precision, and the dual 32-ton hoists allow us to handle large machinery components safely and efficiently. The performance has exceeded our expectations.”

AQ-QDX Double Girder Bridge Crane for a Metal Fabrication Plant in Kazakhstan

A metal fabrication company in Kazakhstan needed a reliable girder bridge crane to handle steel coils and metal sheets inside their warehouse. The project required a balance of high precision, safety, and energy efficiency. After evaluating options, the customer chose the AQ-QDX double girder crane with a 10-ton capacity.

Why this type?

- Compact box girder structure design maximized warehouse space utilization

- Double girder design provided stability and extended lifting height

Customer Review – Mr. Beketov, Operations Manager:

“The AQ-QDX 10-ton crane has greatly improved our warehouse operations. It is precise, energy-efficient, and very stable when lifting steel coils. We are pleased with both the product quality and the installation service provided.”

Looking for the perfect girder overhead crane for your project? In the next section, we’ll walk you through how to select the right girder bridge crane, helping you achieve maximum performance, safety, and efficiency for your lifting needs.

Types of Overhead Crane Girders

The design of an overhead crane girder can be classified by structural form or by girder design.

By Structural Form: Single Girder vs. Double Girder

| Type | Features | Capacity Range | Typical Applications |

|---|---|---|---|

| Single Girder Overhead Crane | One bridge crane girder supports trolley and hoist; compact, economical, easy to install | 5-25 tons | Workshops, warehouses, assembly lines |

| Double Girder Overhead Crane | Two crane bridge girders provide higher stability; trolley runs on rails on top of girders | 10-500+ tons | Steel plants, shipyards, heavy manufacturing |

By Girder Design: I-Beam vs. Box Girder

| Type | Features | Advantages | Common Use |

|---|---|---|---|

| Ovrhead I Beam Crane | Uses rolled I-beam as the crane girder | Simple, cost-effective, ideal for short spans | Light-duty single girder cranes |

| Box Girder Crane | Fabricated box-shaped girder with excellent torsional rigidity and bending resistance | Strong, stable, suitable for long spans and heavy loads | Heavy-duty double girder cranes |

The overhead crane girder design is the core element that determines the strength, efficiency, and safety of any crane system. Whether you require a single girder I beam overhead crane for light lifting, or a double girder box girder overhead crane for heavy-duty, long-span applications, Aicrane has the right solution for you.

But with so many options available, a key question arises: how do you choose the right girder overhead crane for your specific application? Read on to find out.

How to Choose the Right Girder Overhead Crane

Selecting the right bridge girder crane is crucial to ensure safe, efficient, and cost-effective lifting operations. With so many options – single girder, double girder, I-beam, box girder, or customized overhead beam cranes – understanding the key factors will help you make the right decision for your facility.

Load Capacity – Determining Single vs Double Girder

Primary Question: What is the maximum lifting weight required?

Considerations:

- Light Loads (<20 tons): Single girder bridge cranes are typically sufficient, especially for workshops and small warehouses.

- Medium to Heavy Loads (>20 tons): Double girder overhead cranes provide greater stability and allow higher lifting heights.

Span – Evaluating Girder Type and Structural Rigidity

Primary Question: How wide is the area the crane must cover?

Considerations:

- Short Spans (<15 m): Single girder I beam bridge cranes can provide sufficient strength.

- Medium Spans (15–25 m): Stiffer welded I-beams or H-beams may be required.

- Long Spans (>25 m): Box girders or multi-girder configurations are necessary to reduce deflection and maintain rigidity.

Operational Frequency and Duty Cycle

Primary Question: How often and intensively will the girder overhead crane operate?

Considerations:

- Occasional Use: Single girder cranes with I-beam girders are cost-efficient.

- Continuous or Frequent Lifting: Requires stronger girders (box girder or H beam overhead cranes) to prevent fatigue and structural deformation.

Environment – Indoor, Outdoor, and Harsh Conditions

Primary Question: Will the crane operate in a controlled or challenging environment?

Considerations:

- Indoor / Controlled Conditions: Standard indoor overhead crane beams are sufficient.

- Harsh or Heavy Industrial Environments: Heavy duty box girder or custom multi-girder designs provide better resistance to dust, heat, or moisture.

Special Requirements – Load Shape, Hoists, and Custom Needs

Primary Question: Are there any unique lifting requirements?

Considerations:

- Multiple hoists, grab buckets, electromagnets, or oversized components may require double or multi-girder cranes.

- Custom-designed box or multi-girder cranes can handle extreme loads and complex operations safely.

Choosing the right girder overhead crane is not just about picking a model – it must be based on the specific requirements of your project: load capacity, span, operational frequency, environment, and any special lifting needs. Each factor directly influences whether a single or double girder crane, or an I-beam or box girder overhead crane, will provide optimal performance, safety, and cost-efficiency.

Ready to choose the right girder overhead crane for your project? Contact Aicrane to get a tailored solution that perfectly fits your operational needs.

The Role of the Girder in Overhead Cranes

The bridge girder in crane, also known as the overhead crane beam, is the backbone of the crane, directly affecting its strength, stability, and operational performance.

Primary Load-Bearing ComponentThe girder in crane carries the entire load of the trolley, hoist, and lifted materials, ensuring it can safely handle its rated load without deformation. In single girder cranes, the load is concentrated on one beam. In double girder cranes, the load is shared between two beams.

Ensuring Structural Rigidity and StabilityThe overhead crane bridge girder maintains the horizontal and vertical stability of the crane during operation, reducing sway and deflection. It also provides a solid platform for the trolley and hoist to move smoothly, improving operational efficiency and reducing wear.

Supporting Crane ComponentsThe girder forms the foundation for all moving parts of the crane: trolley movement rails, hoist mounting points, electrical conduits and control systems. Proper girder design ensures these components function reliably and safely under load.

How to Assemble and Install Overhead Crane Girder: A Step-by-Step Guide

Proper girder overhead crane installation ensures structural integrity, precise alignment, and safe operation throughout the crane’s service life. This is a guide to assembling and installing bridge crane beams or girders.

Pre-Installation Preparation

- Site Assessment: Ensure the workshop or yard is ready, with adequate space, clear access, and supporting infrastructure.

- Component Inspection: Verify the girders, end trucks, hoist trolleys, and fasteners for quality, dimensions, and damage during transport.

- Equipment Check: Prepare lifting tools, cranes, and safety equipment according to the girder weight and dimensions.

A thorough pre-installation inspection reduces the risk of delays, misalignment, or damage during assembly.

Girder Handling and Positioning

- Transport to Site: Girders are usually transported horizontally on trucks or specially designed frames.

- Initial Lift: Using auxiliary cranes or hoists, the girder is lifted onto temporary supports or directly onto the runway beams.

- Alignment: Ensure the girder is level, parallel to runway beams, and positioned accurately according to design specifications.

Even slight misalignment can cause uneven load distribution, impacting the crane’s performance and safety.

Girder Connection and Welding / Bolting

- Connection Type: Depending on overhead crane girder design, girders are welded, bolted, or assembled using composite sections.

- End Truck Installation: End trucks are mounted onto the girder, with careful attention to axle alignment, wheel clearance, and travel path.

- Trolley Rails: Install rails or tracks for the trolley and hoist, ensuring smooth operation and correct gauge.

Welding should follow industry standards, and bolted connections must be torqued precisely to maintain rigidity.

Final Alignment and Adjustment

- Leveling: Use laser levels or precision measuring tools to check girder height and tilt.

- Straightness: Ensure the girder does not sag or twist along its length.

- Safety Devices: Install end stops, buffers, and limit switches according to manufacturer specifications.

Proper alignment reduces wear on hoists and end trucks, ensures smooth trolley motion, and maximizes crane lifespan.

Testing and Commissioning

- No-Load Test: Move the trolley along the girder, checking for smooth travel, alignment, and mechanical interference.

- Load Test: Lift rated loads incrementally to verify the runway beam crane structural integrity and operational safety.

- Operational Training: Ensure operators are familiar with control systems, load limits, and emergency procedures.

The assembly and installation of the bridge crane girder is a critical step to ensure the crane performs reliably and safely.

To support our customers, we offer professional installation services, including online guidance or on-site assembly, alignment, and commissioning, ensuring your girder eot crane is installed to high safety and performance standards.

Girder Overhead Crane FAQs

What is a girder in overhead crane?

What is the difference between I-beam and box girder?

I beam crane system is economical, lightweight, suitable for single girder light duty overhead cranes.

Overhead crane box girder design uses hollow welded structure with high torsional rigidity, ideal for double girder heavy duty bridge cranes.

Can I install the overhead beam crane myself?

Do you provide girder overhead crane training for operators?

Yes. We offer operator training, including:

- Safe operation procedures

- Load handling techniques

- Emergency protocols

- Basic maintenance

Proper training maximizes crane efficiency, safety, and lifespan.

What safety features are included in girder overhead cranes?

- Limit switches to prevent over-travel

- End stops and buffers

- Overload protection devices

- Emergency stop systems

- Compliance with international safety standards

What is the maintenance requirement for girder overhead cranes?

- Regular inspection of girders, trolley rails, and hoists for wear and alignment.

- Lubrication of moving parts.

- Checking bolts, welds, and structural integrity.

- Adhering to manufacturer guidelines and safety regulations ensures longevity and reliability.

Ready to find a girder overhead crane for your facility? Contact our experts today for a personalized recommendation and quotation.