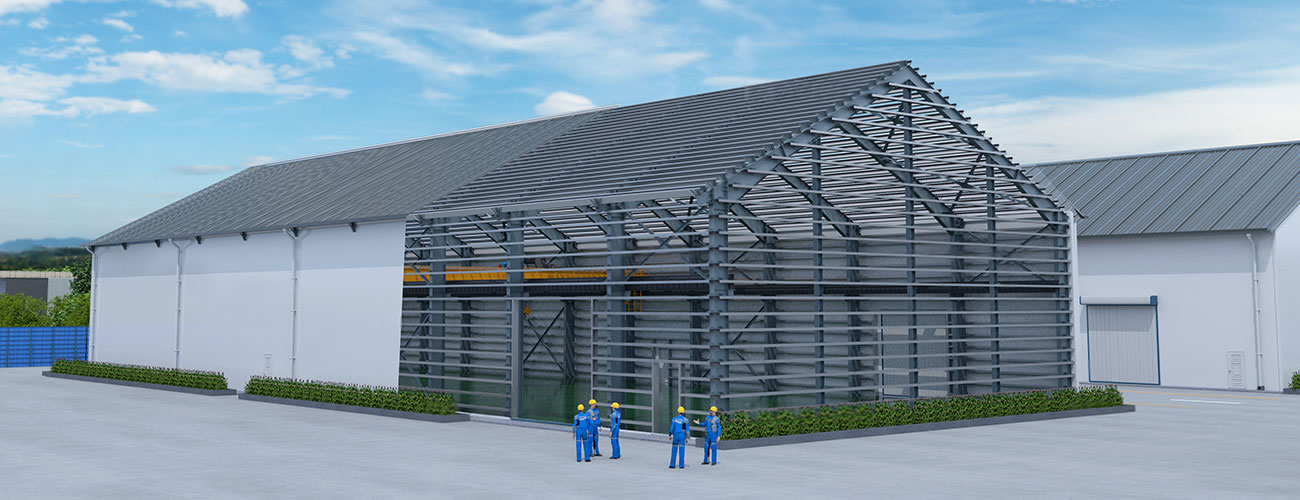

Looking to build a steel structure workshop that fits your production needs and stays within budget? Whether you’re planning a single-layer workshop or a multi-story production facility, making the right design and construction choices is critical. With our integrated EPC approach – covering everything from tailored design and materials sourcing to on-time delivery and turnkey project handover – we help you turn an empty plot into a fully operational, high-efficiency industrial space, ready for fast and reliable production.

Steel Structure Workshop Design: Tailored to Your Production Needs

The first and most critical stage in building steel workshop is design and customization. A well-designed workshop ensures that your production processes run efficiently, machinery and equipment are properly accommodated, and future expansion is possible. As a professional steel structure workshop manufacturer, we specialize in delivering fully customized steel building workshops that are engineered to meet the unique requirements of each client.

Key Customization Capabilities We Offer

- Span & Column Layout: Designed to maximize usable space and optimize production workflow.

- Height & Load Capacity: Adjustable to accommodate small to heavy duty overhead cranes, machinery, and future expansion needs.

- Materials & Panels: Roof, wall, insulation, and coatings selected based on client preferences, climate, and compliance requirements.

- Functional Features: Doors, windows, ventilation, lighting, and fire safety systems can be integrated to meet operational or regulatory needs.

Tailored Steel Structure Workshop Design for Every Industry

We design and build steel workshop buildings for a wide range of applications, with layouts and features fully adaptable to your needs:

- Automotive & Machinery Manufacturing: Single-span or multi-span workshops with high ceilings to accommodate assembly lines, heavy machinery, and overhead cranes (5t–500t). Custom column layouts ensure smooth material flow and flexible production zones.

- Metal Fabrication & Heavy Equipment Workshops: Large span steel structure workshops optimized for large-scale fabrication, welding, and machining processes. Structures are designed to support heavy loads, multiple overhead cranes, and integrated production lines.

- Electronics, Light Manufacturing & Assembly: Single or multi-story workshops with adaptable layouts for assembly stations, clean areas, and office integration. Designed to optimize workflow and space utilization for smaller-scale or precision manufacturing.

- Turnkey Integrated Industrial Parks: Beyond the production floor, we can incorporate offices, staff dormitories, canteens, utilities, and infrastructure as part of a full EPC turnkey solution, delivering a ready-to-use facility tailored to your industry.

How EPC Adds Value in Steel Structure Workshop Design

Our EPC approach enhances every aspect of the design phase:

- Production-Ready Planning: Collaboration with industrial park design institutes ensures layouts match your production flow and eliminate inefficiencies.

- Standards Compliance: We integrate international standards (CE certification, FDA regulations, environmental emission requirements, and NFPA fire codes) during the design phase, ensuring global compliance and minimizing costly retrofits.

- Seamless Handover: Layouts, material selection, and equipment integration are all coordinated to allow “facility ready for production immediately upon handover.”

By focusing on tailored design, you can receive a steel frame workshop that is fully equipped and aligned with your operational needs, laying a solid foundation for manufacturing efficiency, safety, and long-term adaptability.

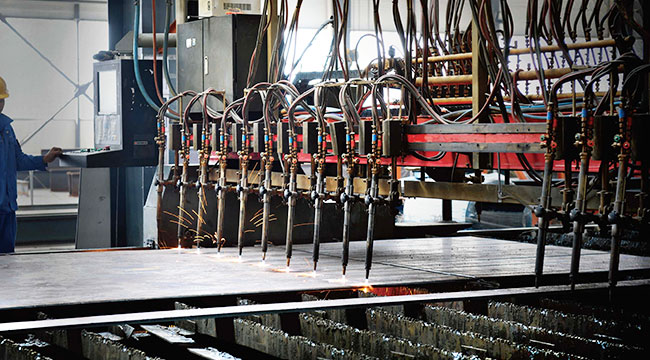

Steel Frame Workshop Manufacturing: Precision Fabrication for Reliable Performance

Once the design is finalized, the next critical stage is manufacturing and fabrication. High-quality steel components and precise fabrication are essential for structural integrity, safety, and long-term performance. As a specialized steel structure workshop manufacturer, we ensure that every piece meets exact specifications and quality standard.

Premium Steel and Components Sourcing for Workshop

Using high-quality steel and components from leading suppliers, such as Baosteel and Sany Heavy Industry, to ensure strength, durability, and compliance with design load requirements.

Strict Quality Control in Steel Workshop Manufacturing

Every component undergoes rigorous inspection, including dimensional checks, welding quality tests, and surface treatment verification, to prevent defects before delivery.

EPC-Driven Efficiency in Workshop Fabrication

Our EPC approach integrates procurement and fabrication schedules with construction timelines. Bulk material management, standardized processes, and centralized oversight reduce costs, minimize delays, and ensure that components are delivered ready for seamless installation.

Our manufacturing and fabrication capabilities ensure that each metal structure workshop component is precisely engineered, high-quality, and ready for seamless on-site assembly, laying the foundation for a safe, efficient, and durable steel structure frame workshop.

Steel Structure Workshop Construction & Delivery: Efficient Assembly and Handover

The construction and delivery stage transforms your steel structure workshop from prefabricated components into a fully functional industrial facility. As a steel frame workshop supplier with EPC capability, we provide comprehensive installation services that ensure safe, efficient, and high-quality on-site assembly – accelerating your path to production.

Professional Installation of Steel Structure Workshops

Our installation service covers the full erection of your steel building workshop, delivered by experienced engineers and a trained construction team:

- Structural Installation: Columns, beams, rafters, bracing, and purlins are installed with precise alignment and secure bolted or welded connections.

- Cladding & Building Envelope: Roof panels, wall panels, insulation layers, gutters, downpipes, skylights, and ventilation systems are assembled to create a fully sealed and functional workshop environment.

- Crane System Installation: Overhead crane beams, runway rails, and supporting structures are installed and calibrated to ensure smooth crane operation.

- MEP Coordination: Doors, windows, fireproofing materials, cable trays, lighting fixtures, and utility interfaces can be integrated according to your project requirements.

EPC Value in Workshop Construction & Delivery

- Faster Time-to-Production: By integrating construction with equipment delivery and commissioning, we enable “workshop completion, equipment ready,” reducing the project timeline by 2-3 months versus local suppliers.

- Turnkey Handover: Upon completion, the workshop is delivered ready for immediate operation, with all structural, mechanical, and utility systems fully installed and tested.

Our integrated installation services, combined with EPC project management, ensure your steel structure workshop kit is assembled correctly, delivered faster, and ready for immediate operation – providing a level of certainty and efficiency that most local contractors cannot match.

After-Sales Service for Your Steel Structure Workshop: Lifecycle Support

Completing construction and handover is not the end of our responsibility – it’s the beginning of a long-term partnership. Our after-sales system is designed to keep your steel workshop buildings operating smoothly, safely, and cost-effectively throughout its entire lifecycle. Whether your facility includes single or double girder overhead cranes, automated production lines, or specialized ventilation and fire-safety systems, we provide continuous professional support to ensure optimal performance.

Dedicated Technical Support

- On-site or remote assistance: Flexible support for global projects, reducing downtime.

- Proactive monitoring: Early detection of structural or crane-related issues before they escalate.

Preventive & Predictive Maintenance

- Scheduled inspections for bolts, welds, roof, walls, and crane systems.

- Optional digital monitoring for deformation, corrosion, and energy use.

- Customized maintenance plans tailored to your production schedule, minimizing disruption.

Fast Access to Spare Parts

- Direct access to factory-manufactured replacement parts ensures compatibility and quality.

- Reduced lead time for critical components like crane rails, panels, and fasteners.

- Standardized parts across multiple projects simplify long-term inventory management.

Long-Term EPC Advantage

- Integrated knowledge: Our team understands your workshop from design to delivery, enabling faster problem-solving.

- Lifecycle value: Beyond repairs, we provide guidance on operational optimization, energy savings, and compliance with evolving standards.

Unlike standard contractors, Aicrane after-sales service is proactive and integrated into the EPC lifecycle, ensuring your steel construction workshop remains safe, efficient, and fully aligned with your production goals.

Value-Added Services for Steel Workshop: Cost, Policy & Long-Term Benefits

Choosing our steel frame workshop solutions offers more than just a turnkey facility. Through EPC integration and strategic partnerships, we provide additional value that extends beyond construction, helping your project achieve higher efficiency, lower operating costs, and long-term competitive advantages.

Integrated Efficiency & Cost-Reduction SolutionsWe leverage partnerships with leading technology and energy companies such as Huawei and CATL to implement a “Construction + Digitalization + Renewable Energy” approach. This enables smart, zero-carbon industrial parks and optimizes energy consumption, workflow efficiency, and operational costs throughout the lifecycle of your steel structure for workshop.

Financial & Policy SupportWe coordinate with import/export banks, the Silk Road Fund, and other financial institutions to provide clients with low-interest financing options. At the same time, these projects are more easily included in national or regional development plans, giving your steel structure workshop factory preferential access to infrastructure, utilities, and policy support.

Long-Term Value Beyond ConstructionBeyond delivering a high-quality steel structure workshop building, we help clients unlock additional value through supply chain connections, tax incentives, and long-term operational guidance. This ensures your steel structure building workshop remains efficient, compliant, and adaptable to future growth or upgrades.

Steel Structure Workshop FAQ

What are the common steel structure workshop types?

What determines the price of a steel structure workshop?

How much does a steel structure workshop cost per square meter?

Can the structural steel workshop support overhead cranes?

How do site conditions affect steel building workshop design and cost?

How long does it take to build a steel structure workshop factory?

What is the expected lifespan of a steel frame workshop?

Can the metal structure workshop be expanded or upgraded in the future?

Looking to build a steel workshop? Contact us today to discuss your steel structure workshop requirements and receive a customized proposal. Let us help turn your production vision into a turnkey industrial facility – delivered on time, on budget, and built to last.